want to learn more?

Get in touch with our technical team to learn more about how the Cumulus Quality Management System (QMS)

can help with your welding inspections.

Conduct compliant weld inspections with precision, every time.

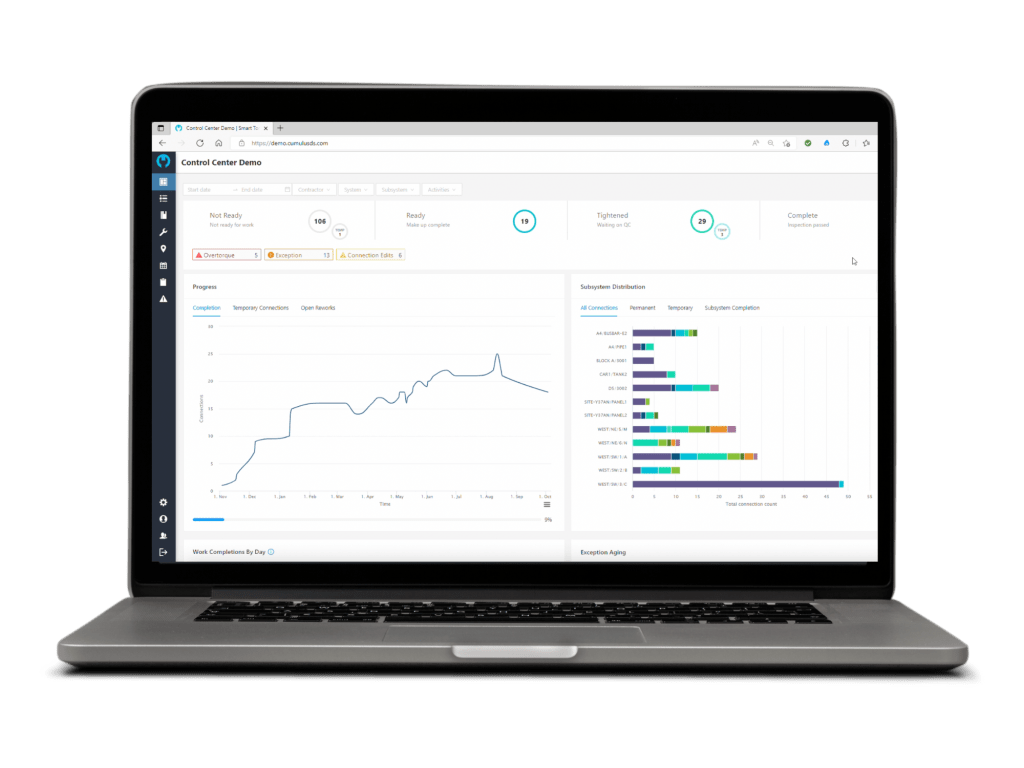

The Cumulus Quality Management System (QMS) is designed to guide weld inspectors through every step of the inspection process. Transform engineering code and standard operating procedures into digital workflows, empowering welding inspectors to ensure compliance and capture valuable quality data.

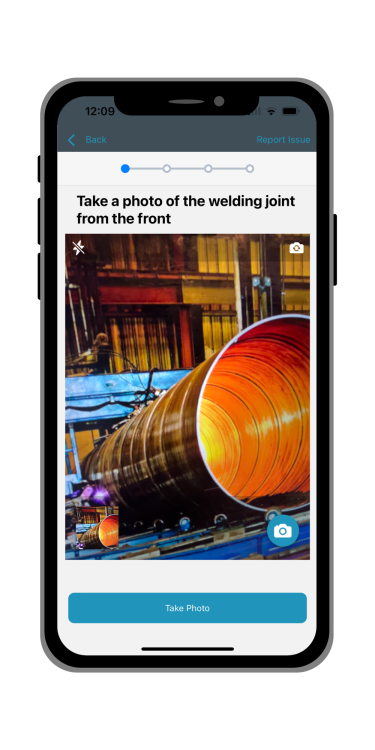

Every inspection can require inspectors to record various measurements, validate information, and take photographs of the weldments. Then, a completion report is automatically triggered, with any quality discrepancies immediately flagged. Never overlook a critical inspection element with Cumulus QMS.

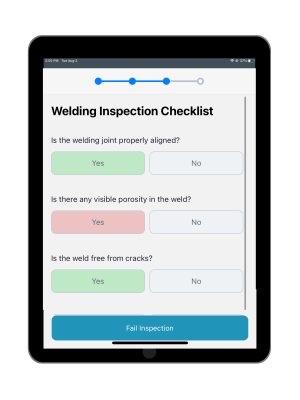

The Cumulus system is designed to guide inspectors through each step of the inspection activity. This includes a structured workflow that ensures all necessary inspection tasks are completed systematically. By guiding the inspectors, the system minimizes the chances of overlooking critical inspection elements.

Throughout the inspection process, inspectors can utilize the Cumulus system to record various measurements, validate information, and take photographs of the weldments. This capability ensures that all relevant data is captured accurately and efficiently. The system also allows inspectors to review the historical data of the weldment, providing context and aiding in a more informed assessment.

The system is adept at identifying critical properties of the weldment, such as engineering codes, material thickness, and other relevant specifications. These properties are crucial as they provide the acceptance criteria for the inspector to evaluate the quality of the weld. By having immediate access to these specifications, inspectors can make more accurate and informed decisions.

As inspectors input data, the Cumulus system actively monitors these inputs against the predefined acceptance criteria for the specific weld. If an input falls outside the acceptable parameters, the system flags this discrepancy immediately. This feature is vital for ensuring that all aspects of the weld meet the necessary specifications.

Upon completion of the inspection, the Cumulus system generates an automated PDF report that encapsulates all the details of the weld inspections and related activities. This report includes measurements, photographs, compliance information, and any flagged issues. The automated nature of this reporting not only saves time but also ensures that all relevant information is accurately and comprehensively documented.

Get in touch with our technical team to learn more about how the Cumulus Quality Management System (QMS)

can help with your welding inspections.

Get ready to build your first weld inspection workflow in less than a minute.

Download the app to start your free trial.